Introduction

When budgets are tight and missions are non-negotiable, every commander knows gear failure is a readiness killer. Corrosion from salt fog, sand intrusion, or electronics ruined by shock can sideline assets in minutes.

This damage often stems from environmental exposure rather than enemy action. The good news is that most of these losses are avoidable. This article breaks down field-proven methods for protecting military equipment in the harshest theatres.

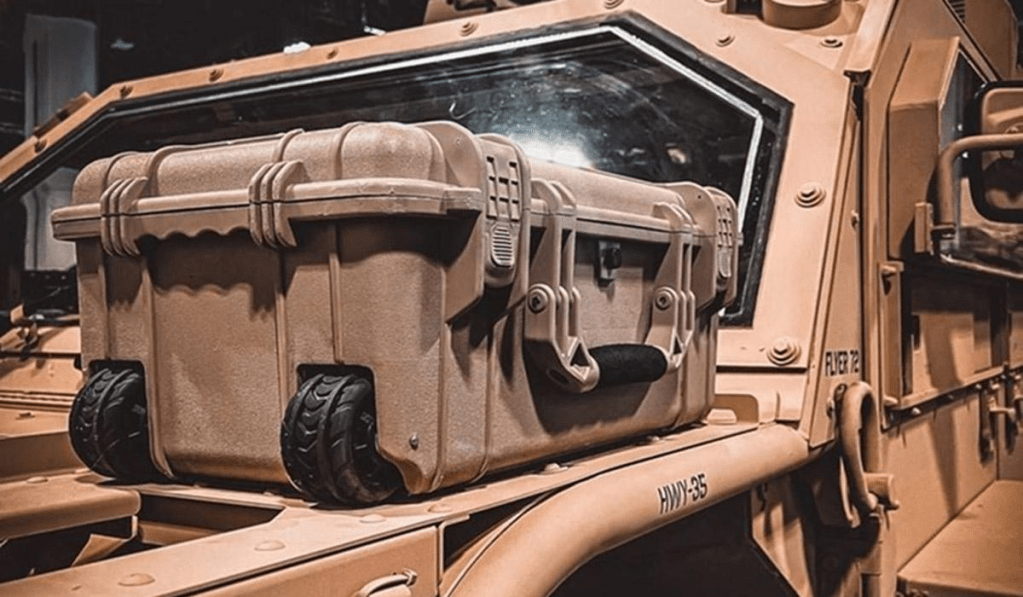

1. Why Military Gear Needs Rugged Protective Cases

High-value items face relentless punishment in the field. Talcum-fine dust blasts bearings during desert deployments, while salt spray corrodes contacts on maritime patrols within days. Extreme temperature swings can warp polymer housings and fracture solder joints.

Continuous vibration during convoy movements slowly backs out fasteners. These physical stressors eventually micro-crack circuit boards. Reducing equipment turnover is also vital for sustainability goals.

Moisture, Condensation, and Corrosion

Even watertight containers face risks. Condensation forms inside as gear cools during altitude changes or air-cargo flights. Humidity above 60% accelerates corrosion on uncoated metals.

Quick-Hit Maintenance Best Practices

- Wipe down housings with mild detergent immediately after saltwater exposure.

- Add replaceable desiccant packs inside storage cavities to manage internal moisture.

- Schedule 30-day visual inspections to verify the integrity of rubber gaskets.

A properly specified protective enclosure acts as the first line of defence against these threats.

Tip: Do not assume a watertight seal guarantees safety. Rapid altitude or temperature changes can create internal condensation. Always utilise desiccant packs and inspect rubber gaskets monthly to prevent silent corrosion from destroying electronics from the inside out.

2. Choosing the Right Custom Case for the Mission

Selecting the correct protection requires moving beyond standard-issue bins. For specialised equipment, engineering solutions like durable custom hard cases from Royal Case Company are designed to meet specific environmental standards. Understanding core specifications helps procurement officers select the right tool for the job.

Core Specs Checklist

- Shell Construction: Injection-moulded polypropylene offers high impact resistance with lighter weight. This makes it ideal for man-portable loads. For oversize loads, roto-moulded polyethylene increases wall thickness and durability.

- Certification Benchmarks: For military and defence applications, reliable performance in extreme conditions is a necessity. The Ingress Protection (IP) rating system, defined by the International Electrotechnical Commission (IEC) standard IEC 60529, provides specific, quantifiable data on a device’s resistance to solids and liquids.

- IP67 is sufficient for protection against rain, splashes, or temporary, accidental drops into shallow water.

- IP68 is preferred for military-grade equipment because operations in wet environments, such as maritime communication or ground operations in flooded areas, may require prolonged or deeper submersion.

- Many military-grade devices are tested to both IP68 standards and the broader MIL-STD-810 standard, which covers additional factors like shock, vibration, and temperature extremes.

- The US military generally seeks the more robust and flexible protection of an IP68 rating to ensure equipment functionality in the most demanding and unpredictable environments.

- Environmental Endurance: Cases must offer chemical resistance to withstand JP-8 spills. Pressure-relief valves are also essential to equalise cabin-to-ground altitudes. This prevents vacuum lock and lid-sealing failure.

- JP-8 is the military equivalent of Jet A-1 with the addition of corrosion inhibitor and anti-icing additives; it meets the requirements of the US Military Specification MIL-T-83188D.

- It is the dominant military jet fuel grade for NATO air forces.

Interior Engineering

The exterior provides the shield, but the interior protects the precision. Custom foam inserts cradle irregular shapes to keep optics zeroed and gimbals aligned. For servers, rack-mount frames rated to absorb 40 g shocks are critical.

Tip: While custom-engineered cases carry a higher initial price tag, their superior impact resistance and IP ratings significantly extend equipment life. In the long run, investing in custom specs is cheaper than frequently replacing broken standard-issue bins.

3. Environmental & Maintenance Force Multipliers

Consistent care ensures the longevity and reliability of your equipment.

- Thoroughly clean and dry all gear before placing it in storage.

- Swap out desiccant packs every 30 days or as soon as the indicator colour shifts.

- Inspect gaskets for cracks and test latch tension on a monthly basis.

Using a properly specified enclosure significantly enhances the effectiveness of these preventive measures.

Tip: Equipment protection does not end at purchase. Establish a strict x-day schedule to inspect latch tension and replace colour-changing desiccant packs. This simple routine ensures your IP68 rating actually holds up during combat operations.

Summary

Operational readiness hinges on more than training schedules; it starts with gear that works on demand. By recognising the environmental gauntlet equipment faces, units can better prepare for the field. Selecting cases engineered to meet mission-specific standards is a crucial investment.

Verifying real-world performance through field-tested scenarios reduces downtime and safeguards budget lines. For teams evaluating new deployments, a technical consult is the next logical step. Specialised engineering staff can review load lists to provide a tailored specification package.

Missions may change, but environmental physics never do. Invest in the right protection now, and your gear will answer the call every time.

Author Profile

Royal Case is the leading manufacturer of custom wholesale cases for businesses across every industry.